Turminha,

Vejam o que encontrei no face. Muito interessante os diversos tipos de zimmerit utilizado nos veÍculos Alemães.

https://www.facebook.com/panze.../?type=1&theater

Turminha,

Vejam o que encontrei no face. Muito interessante os diversos tipos de zimmerit utilizado nos veÍculos Alemães.

https://www.facebook.com/panze.../?type=1&theater

Replies sorted oldest to newest

Bom, no link da fanpag tem muito mais imagens de padrão de zimmerit e imagens de veículos.

A impressão que tenho é a de que eles jogavam o produto por cima da blindagem e depois vinham fazendo as marcas de forma que eles preferiam.

Como nessa imagem.

Essa última chama a atenção.

Gosto dessa foto.

Bom, no link da fanpag tem muito mais imagens de padrão de zimmerit e imagens de veículos.

A impressão que tenho é a de que eles jogavam o produto por cima da blindagem e depois vinham fazendo as marcas de forma que eles preferiam.

Como nessa imagem.

Cledson o zimmerit era normalmente aplicado nas fábricas e determinados grupos de blindados recebiam determinado tipo de zimmerit. Esse do Tiger I que mencionei é muito raro para este veiculo - o tipo "waffle - que era muito comum nos Sturmgeschutz.

Nas imagens o zimmerIt sendo aplicado em um panther na fábrica.

Abs - Manoel Henriques

Gosto dessa foto.

Fernando bem legal essa imagem! ![]()

Vi um dia desses uma foto de um KT com zimmerit no chassis e mas não na torre....

Abs - Manoel Henriques

Copiei do fórum do World of Tanks.

http://forum.worldoftanks.com/...rit-on-german-tanks/

ZIMMERIT: by Donald Spalding

Production and Application Methods

From: AFV NEWS, Jan-Apr/1983 issue

This information is from a secret British Intelligence Objectives Sub-Committee report. The information is now unclassified and entitled,"Zimmerit" Anti-Magnetic Plaster for AFVs, which was reported by MajorJ.W. Thompson and Mr. C.E. Hollis. The report is dated July 1945, and is not complete due to insufficient information, or the failure to locate persons with detailed knowledge of the subject.The investigation was started with the hope that a way might be found to defeat magnetic mines used against British armor in the war with Japan.

In 1943 the Germans adopted a thick coating for the vertical armored surfaces of their tanks. This coating was designed to defeat the affects of mines placed on armored vehicles, mainly tanks, by determined Russian infantry assault teams. The mines were attached to the tanks and held in place by magnets built into the bottom of the mines. The function of the "zimmerit" was simply to provide a non-ferrous magnetic gap between the steel armor and and the magnets, in other words a non-magnetic stand-off.

Early in 1944 samples of zimmerit were taken from captured vehicles and instructions for its use obtained from prisoners of war. The composition of zimmerit was analyzed by C.S.A.R. and found to be the following:

Polyvinyl Acetate-25%, as binder or glue; Wood Fiber-10%, as filler; Barium Sulphate-40%; Zinc Sulphide-10%; Ochre Pigment-15%, for the dark yellow color.

On August 14, 1945 the investigating team visited the Henschel Werke at Kassel, Germany and interviewed the Director of Production and Production Engineer. The following information was obtained. The zimmerit was received in drums from Chemische Werke Zimmer in Berlin, but they thought production had taken place in various centers because of the large scale demands, and because of factory dispersal.

The material arrived in a consistency of soft putty (others have compared it to paste, plaster or plastic). It contained a volatile solvent smelling like acetone. No thinners were added before use as it worked very easily even when handled by inexperienced personnel.

The surface of the tank did not need to be prepared before applying zimmerit, but it was normal to coat the vehicle with anti-corrosive primer. The zimmerit was applied to the surface in two coats, using a sheetmetal trowel. The first coat was 5mm thick and was marked out in squares using the edge of the trowel. This coat was allowed to dry at ordinary temperatures for 24 hours. The second coat was applied thinner and marked in wavy lines with a metal comb. The criss-cross squares increased the adhesion of the second coat, while the comb markings gave a camouflage finish, plus poor contact for mines.

After the application of both coats, the surface was treated by a gas blow-lamp to harden it. This took about an hour per tank and no difficulty was experienced in getting satisfactory hardness without the zimmerit becoming brittle. (I have seen samples of aged zimmerit and it reminded me of compressed sawdust.) During the hardening process the solvent was removed by the heat of the blow-lamp on the surface. The chief thing to watch was not to leave any soft spots which could be brushed off the vehicle if not hardened properly. If the zimmerit was not heated with a blow-lamp it took eight days to harden. This was impractical considering

the urgent need of tank delivery to the front.

The Production Engineer of Henschel Werke said that the company did not help in the development of zimmerit, but simply applied it to vehicles. He thought that zimmerit was dropped late in the war due to the development of better anti-tank weapons. No mention was made of how successful zimmerit was, however, when the British Army captured the Henschel Werke they

removed about 100 tons of zimmerit. The investigating team next visited the Karl Freudenburg A.G. in Weinheim, Germany and talked with the companyÍs Polyvinyl Acetate experts. Again, this company had not helped in the development of zimmerit, but

did work on the P.I.B. mineral oil adhesives for sticky bombs. The Polyvinyl Acetate was used as an emulsion in camouflage paints and as a solvent such as Ethyl Acetate and Toluene during the war. It was mentioned that C.W. Zimmer of Berlin was well known for paint manufacture during that time, and probably used Polyvinyl Acetate.

On visiting I.G. Farbenindustrie A.G. Hochst, Germany, the Plastics Development Manager and Production Manager were interviewed. They said that they had heard of the C.W. Zimmer Co., but also knew nothing of the development of zimmerit. It was also mentioned that such things were kept secret. After referring to the companyÍs records it was learned that Mowilith 20 (a Polyvinyl Acetate) was sold to the C.W. Zimmer Co. in July 1943, but they had no idea if the company or its personnel still

existed.

The general properties of Polyvinyl Acetate were discussed. Mowilith 20 was 50% benzene solution (this is what smelled and was burned off with blow-lamps). It had an average MW of 3500 (Staudinger viscosity method, 1 - 2% solution) and a melting range of 40 to 50 degrees C. It was also confirmed that the blow-lamp would remove the solvent and adhere the zimmerit to the armor, thus increasing its resistance to shock. In regard to adhesion, it was suggested that a clean or just painted surface would be better than a greasy or rusty one. Also, that Polyvinyl Acetate with a pigment mixture (zimmerit had 15% ochre) were somewhat water-resistant, but due to thermal behavior of Polyvinyl Acetate its use was limited in plastics as it became brittle when cold.

In conclusion, the team decided that the C.W. Zimmer Co. was responsible for zimmerit and every effort should be made to contact them. They also were wondering if zimmerit, thinned down, could have been sprayed on vehicles to speed up application time. However, no follow-up research was done due to the end of WW2.

I wish to gratefully acknowledge the help of the staff of the Imperial War Museum who made this article possible.

hahahaha!!!

Tem como resumir em portugues? rsrs!! ![]()

![]()

![]()

hahahaha!!!

Tem como resumir em portugues? rsrs!! ![]()

![]()

![]()

Vou ver se traduzo depois. ![]()

Mais uma imagem.

Mais uma imagem.

Gosto destas fotos ![]()

hahahahaa!!!

Só porque apareceu um soldado Ingles conferindo sua presa. rsrs!! ![]()

hahahaha!!!

Tem como resumir em portugues? rsrs!! ![]()

![]()

![]()

Eitcha que Santo de casa não faz milagres mesmo...

Eu escrevi um artigo sobre isto há muitos anos atras, aqui mesmo na Webkits:

Eis a coisa, Cledson...em bom portuga:

http://www.webkits.com.br/news...id=379&zoneid=28

E se quiser fazer o zimmerit com ferro de solda, eis uma dica:

http://www.webkits.com.br/news...id=380&zoneid=28

Esta técnica parece perigosa, mas é mamão com açucar...é só treinar em uma sucata e voiláá´...

Bom proveito !!!!

Rapazzzz!!!

Serra, tu mandou ver nesses artigos. Muito show! ![]()

![]()

Rapazzzz!!!

Serra, tu mandou ver nesses artigos. Muito show! ![]()

![]()

A gente semos tudo phodah !!!!

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Valeu !! Fiz uma releitura da bagaça....muito legal mesmo !

O último tigre que eu montei eu fiz o zimerite com massa putty Tamiya. Ficou bem legal.

E usei um pedaço de serrinha Starret (de arco de serra) pra fazer os traços do padrão do zimerite. Com um pouquinho de prática fica bem legal.

Tem ferramentinhas próprias para isto mas como na realidade são uma espécie de espátulazinhas dentadas...uma serrinha também resolve ![]()

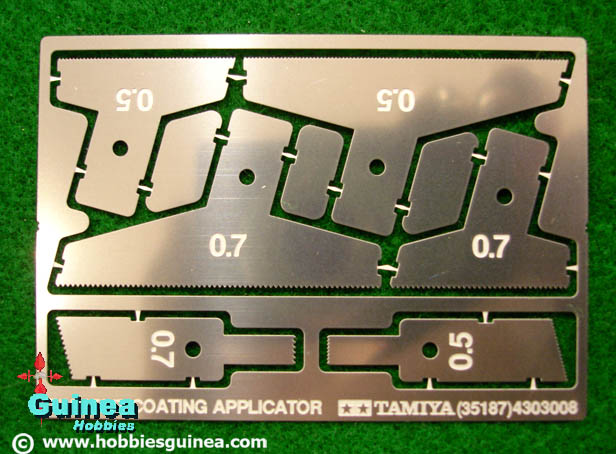

Ferramentinha da Tamiya.